From doors to bulletproof vests: How Kyiv entrepreneur counters burglars and supports military

How a Kyiv entrepreneur who has spent his entire life manufacturing armored doors began producing body armor

Business Censor is resuming its regular column "Business Heroes." During the full-scale invasion, we will share stories about entrepreneurs who not only produce goods and create jobs in Ukraine, supporting the economy, but also assist the Defense Forces in resisting the occupiers.

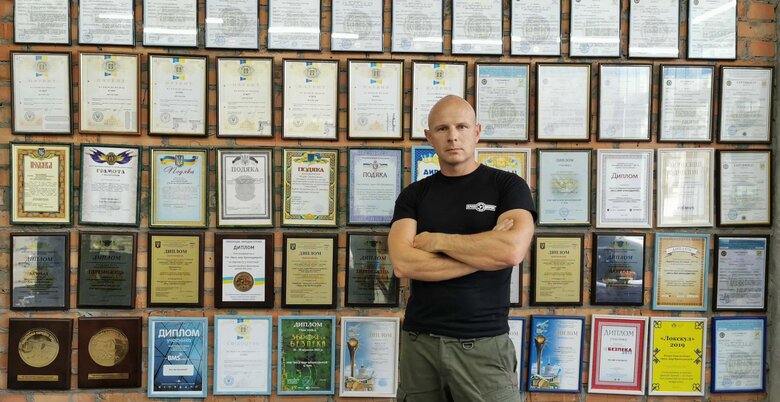

Today, we present the story of entrepreneur Ihor Omelchenko from Kyiv, who has been manufacturing armored doors for over a quarter of a century. Since the war with Russia began, he has started producing bulletproof vests and specialized doors for shelters.

The first patent and bulletproof doors

"I can say I’ve been involved with doors since 1998. I started by putting up flyers for a door manufacturing company when I was still a student. Then, I was offered to sell doors myself," Ihor Omelchenko recalls.

He remembers that in the early 2000s, Ukraine experienced a real boom in demand for armored doors, which motivated him to start his own production.

"In 2002, I registered as an individual entrepreneur; I was 22 years old and still studying at university. By 2006, we registered the company, Ves Mir Bronedverei LLC, which is still operating today," Omelchenko adds.

Later, he registered his own armored door brand, Bodyguard, with the motto "Our product is your safety." However, in the early years, the business was challenging, the market was highly competitive, and many manufacturers tried to undercut prices by offering armored doors made from low-quality materials.

"Selling quality doors was difficult, and I didn’t want to deceive customers like some other manufacturers did. That’s why, as early as 2004, I was one of the first to certify armored doors for compliance with the Ukrainian standards (DSTU). Since then, all my products have quality certificates," the entrepreneur explains.

This strategy proved successful. By 2008, Omelchenko’s enterprise employed several dozen workers.

That same year, representatives of one of the well-known mayors approached him with an order for bulletproof doors.

"We underwent the necessary certification specifically for this client. At that time, we were the first in Ukraine to certify armored doors simultaneously for the highest burglary resistance and bullet resistance classes, and we began producing Bodyguard protective armored doors. In other words, we became not just a manufacturer of armored doors, but of bulletproof doors. That’s probably when our journey toward producing bulletproof vests began," the entrepreneur explains.

Bulletproof vest for patriots

To manufacture bulletproof doors, Omelchenko had to order high-quality ballistic steel from Sweden, as it needed to withstand bursts from automatic rifles.

"Since then, we have experimented with various materials, studied impact resistance and deformation, and researched ballistic steel manufacturers. It turned out that, without even realizing it, we were preparing for 2014 while making these doors," the entrepreneur says.

He recalls that at the height of the Revolution of Dignity, activists approached him with a request to produce bulletproof shields.

"They saw that we were producing bulletproof doors and asked us to make bulletproof shields for them. We happened to have a sheet of ballistic steel; we cut it, welded on handles, and made several openings so they could see through. It was crude but effective," Omelchenko recalls.

Just a few months after that unusual order, the Russian occupiers invaded Crimea, and later the Donetsk and Luhansk regions. At that time, the military urgently needed bulletproof vests.

"It so happened that we already had extensive experience working with ballistic steel and a stock of materials. So, we developed a bulletproof vest from scratch and certified it in April 2014. At that time, we were probably producing the largest number of bulletproof vests in Ukraine. Fighters from the Donbas Battalion came to us, our bulletproof vests were in Ilovaisk, and with the defenders of Donetsk airport," Omelchenko says.

"So, in the first half of 2014, we managed to quickly meet the urgent needs of the military. Later, other manufacturers were able to scale up production and began winning government tenders," he adds.

However, work on our own bulletproof vest did not stop. We decided to name it "Patriot."

"Maybe it sounds a bit loud, but in reality, it was the patriots who were carrying them at that time," Omelchenko explains.

Within a short timeframe, they managed to produce about 5,000 such bulletproof vests.

"We bought the armor, cut it, bent it. At the same time, sewing workshops, from small to large factories, were making plate carriers and pouches," the entrepreneur says.

However, later the state began purchasing bulletproof vests from a single large manufacturer, and more than 2,000 vests remained unused in Omelchenko’s warehouse.

"I even considered disposing of them because we had to pay for storage. But I reassured myself that if the enemy came again, I could outfit several battalions at once," Omelchenko notes.

And on February 24, 2022, he realized he had been right.

"When the first day of the invasion began, I already knew what I had to do and where to go. Some of the vests were fully ready and just needed to be assembled, while others still required finishing. I called the workers and said: doors are no longer needed, we have to make armor again. We worked from morning till night. Everything went straight to the front," the entrepreneur recalls.

Several hundred bulletproof vests were given free of charge directly to the defenders, while the rest were sold at cost to volunteers who raised funds for specific military units on the front line. Omelchenko explains that the minimal prices did not cover expenses, but at least ensured that the vests reached where they were truly needed, rather than ending up in warehouses or with resellers.

Although his company holds certifications for fourth- and fifth-class bulletproof vests, Ihor Omelchenko jokingly calls the products made in the first months of the full-scale invasion "first-month armor," which helped hold the line until aid began arriving from abroad.

"Sometimes we made the simplest plate carriers, there was no fabric. You don’t make a complex ballistic vest when a battle is underway. But our armor was high-quality: we had a damping layer and anti-ricochet protection; constant certification work and lab testing taught us a lot. And back then, if you remember, there were cases when plates were welded from leaf springs," the entrepreneur says.

Later, the state managed to organize mass procurement of bulletproof vests, but Omelchenko’s company continues to support the military.

"There was a request for anti-HEAT slat armor; we conducted extensive research and testing. There was also a request from the 3rd Assault Brigade: they asked us to develop a trench armor shield that would be lightweight and compact. Since we also produce full-size Class 6 ballistic shields, we designed a reduced shield, the ‘Patriot Maliuk,’" Omelchenko notes.

His company, Ves Mir Bronedverei, is also capable of producing ballistic helmets. Development began back in 2014, but demand quickly faded. As a result, only designs and prototypes remained. In 2022, they resumed development and promptly manufactured and certified a batch of "Patriot" ballistic helmets.

"When bulletproof vests became less needed, we continued making doors."

In recent years, however, the state gained the ability to purchase sixth-class protective bulletproof vests with ceramic plates, so Omelchenko’s enterprise returned to working with armor for doors.

"We are a manufacturer of armored doors, but when the country needed bulletproof vests, we started making bulletproof vests. When bulletproof vests became less needed, we went back to making doors. Sometimes people even call us ‘armored doors–bulletproof vests.’ It’s like our callsign," the entrepreneur says.

At the same time, demand for civilian products is also affected by the war.

"For example, now we produce armored doors for civil protection shelters. It turned out that our 12 years of experience experimenting with blast resistance of doors has also come in handy here," he adds.

Omelchenko describes himself as a creative person, and creative people, he says, cannot do nothing, so he constantly tries to improve production technology. He also professionally studies the enemy—burglars.

"I have personally studied over 1,500 apartment burglaries: what tools burglars use and how they operate. I even visit the most interesting cases myself. Maybe I have gathered the largest such database in Ukraine; some ‘exhibits’ I even keep in my museum," he shares.

Omelchenko explains that thoroughly studying the methods of criminals allows him to find solutions to counteract them more effectively. Over the years, he has registered about 10 patents for his developments, with some still in the process of registration.

"Why patents? Because many of my developments, unfortunately, competitors pass off as their own. And that’s a disaster. Unfortunately, even with a patent, it is very difficult to prove rights violations in Ukraine," Omelchenko admits.

The hardest part is proving that a specific company used the patented technology. Many manufacturers operate non-transparently, making it difficult to hold them legally accountable.

However, one can always set more challenging goals. Omelchenko says his company, Ves Mir Bronedverei, holds 17 registered records in Ukraine. The latest is for doors that, during certification tests for resistance class 4, were supposed to hold for 10 minutes but withstood 240 minutes.

The entrepreneur explains that there are quality standards doors must meet. One of the most prestigious is the European EN-1627. Omelchenko claims that his company was almost the first in Ukraine to get certified to the highest protection level, class 6, under this standard back in 2008.

According to him, Bodyguard armored doors of the highest protection class have never been breached in nearly two decades, despite dozens of attempts.

He tries to track and analyze all such cases and says that even Russian occupiers failed to break through these doors in Bucha, Irpin, and other Kyiv region cities at the start of the full-scale war in 2022.

"We’ve actually made doors for many clients: for numerous embassies and we’re still working on some embassy projects right now, as well as for banks. One project I can mention is installing vault doors for the VIP branch of Diamantbank. That bank no longer exists, but the doors are still there," Omelchenko says, sitting at a table with a vault door instead of a tabletop.

Recently, new special orders have also been coming in, he adds. For example, his company is currently developing "anti-raider armored doors."

"It’s one thing when law enforcement uses specialized tools to break doors. I believe lawful demands must be met, and I periodically conduct training and exchange experience with certain special units. It’s a different matter when reliable doors need to provide enough time for law enforcement to be called and arrive," Omelchenko explains, noting that such requests are increasing.

However, if needed, the entrepreneur is ready to resume producing products for the country’s defense: "If the authorities say the guys are supplied, then I’m calm. But I’ll remind the occupiers of a well-known line from a song about Ukrainian Kakhovka: ‘Our armored train stands on a side track.’"