In winter without jackets: how change in fabric stopped delivery of 100,000 jackets for AFU

The Ukrainian Armed Forces will not receive 50,000 winter jackets in September, and the delivery of another 50,000 in November is also in doubt. The reason for this is a shortage of fabric used for the outer layer of windproof and waterproof jackets.

How this happened and who is to blame, we will tell you below.

Since the full-scale invasion, almost every autumn begins with problems with windproof and waterproof jackets (WWPJ). In the autumn of 2022, it was not bought from a domestic manufacturer until the last moment, and then it was bought in Turkey through VECTOR AVIA and a relative of MP Kasai or through the American company Sinclair & Wilde. Hello, scandals with Reznikov's jackets, which Censor.NET has written about more than once.

In 2024, the "State Logistics Operator" purchased 75,000 jackets from "Farminko Nord", which submitted documents about 20 workers hired on the same day, but went to Vietnam to sew jackets. As a result, the jackets were sewn late and were not accepted by the Central Quality Control Department of the Ministry of Defence.

But in 2025, problems with the jackets began in the spring.

In May 2025, more than 20 procurements of clothing announced by the SE "SLO" were disrupted. None of the Ukrainian suppliers submitted bids, which is an anomaly for this customer.

According to market participants, the reason for this was the low estimated price set by SLO. According to Ukrainian producers, such a price made it impossible to ensure even minimal profitability of supplies. Instead, the SLO claimed that suppliers had bargained for lower prices with other customers.

The situation was further complicated by the fact that the SLO requested prices from foreign producers. This was perceived by the Ukrainian market as an attempt to displace them in favour of Turkish and Chinese goods.

The prices were indeed lower than those of other customers and lower than the previous year, which was surprising. According to Oleksandr Sokolovskyi, owner of "Textile Contact", prices were reduced by 13-27% compared to the end of 2024.

(Read more about the situation here)

Instead, the agency's representatives indirectly hinted at a cartel conspiracy by Ukrainian market participants to keep the price favourable.

In any case, out of 18 nomenclature items, 11 items were not tendered. The list included 115,000 windproof protective jackets.

The confrontation between SLO and the manufacturers lasted for 2 months. During this time, with the intervention of the Public Anti-Corruption Council, two meetings were held where the parties tried to find a common language.

What were the producers' arguments?

- To comply with the SLO requirements, they needed to make more efforts than other customers: including more inspections and examinations of goods, as well as special packaging on pallets, which increased the number of vehicles involved from 7 to 27.

- Some of the orders they fulfilled for other customers were less than a thousand. That is, they sold the leftovers at a low price. In addition, the producers actually admitted that they often gave to other customers what had not passed the quality checks of the SLO and the CQCD (Central Quality Control Department of the Ministry of Defence of Ukraine).

- Linking to 2024 prices is irrelevant, as prices for gas, electricity and raw materials for products supplied from abroad have risen since then.

- Increased transportation costs (2-5 times).

- Unilateral responsibility of the manufacturer (penalties for deviations are higher than for other customers).

- The risk of late deliveries due to force majeure, even if the CCI certificate is available.

What was the SLO's reasoning:

- In 2024, fines were reduced (from 0.5% to 0.2% per day of delay).

- The SLO requires compliance with SLAs, technical control points, etc.

- If there is a justification, it can agree to extend the contractual deadline. It takes into account force majeure.

"You received a one-year contract with normal terms, and this year you will remember that we are also working with the procurement department to move it up another month to make it better. We started bidding in early November 2024. And now we are planning to do it in October. I understand that you want it to be in the summer, so that the raw materials are there and so on. But in the conditions we are working in, we are also restructuring the work of the Logistics Forces Command," said Viktoriia Vinohradova, head of the relevant department, at the second meeting.

"Indeed, quality control requires additional costs. At the same time, we observe that at the procurement stage, participants declare certain manufacturers, while during the execution of the contract, other manufacturers are often added, let's say, for subcontracting, which, in turn, leads to an increase in the number of batches, and, accordingly, an increase in the number of samples, which, in fact, entails additional costs for checking such batches," added the SLO representatives.

Eventually, in June, the SLO revised the estimated cost for a number of nomenclatures. Despite this, not all re-auctions were successful. In particular, when the price was raised by 2.1%, the SLO failed to auction the jackets. Successful bidding took place only in July.

It would seem that everything is fine. We can exhale. Time is running out. But in principle, we could have the jackets by October.

But then the problem came from the other side. "Versakhem" (one of the suppliers of the jackets) asked the Central Logistics Department of the Ministry of Defence to provide clarification on the fabric of the Cherkasy Silk Mill.

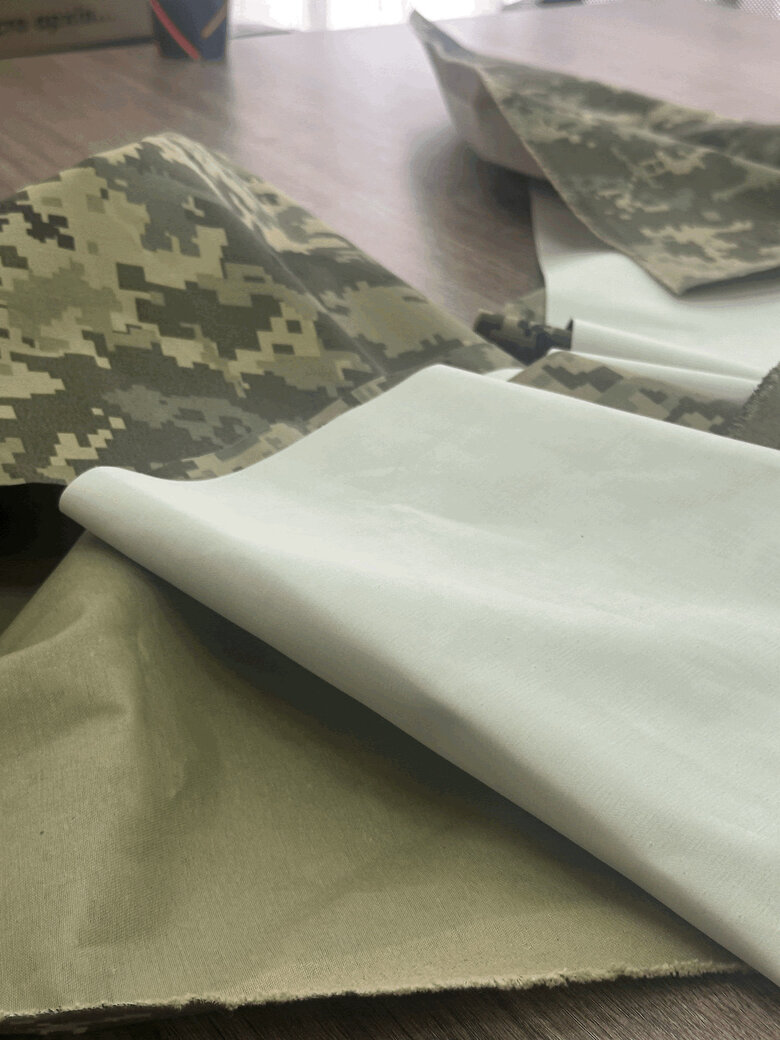

The problem was that, having failed to receive the necessary materials for production from Germany, the plant produced a new fabric that was similar in parameters to the TU (technical specifications) for the jackets, but different.

In July, the situation with the fabric was brought to the collegial body that reviews changes to the TU. Why?

Because in order to approve the fabric, a jacket made of the new fabric must be worn by the military and receive feedback. And they have to wear it only in winter because it is a winter jacket.

It is worth noting that the fabric was coated with a film rather than a foam material to protect it from water. This changed its technical characteristics in a number of points. In some cases, the indicators were even higher.

Therefore, at the Collegial meeting in July, the fabric was treated rather kindly.

"If it passes the tactical and technical characteristics, then there are no questions. What comment could you write if you were brought this jacket? Nothing," was one of the remarks during the meeting.

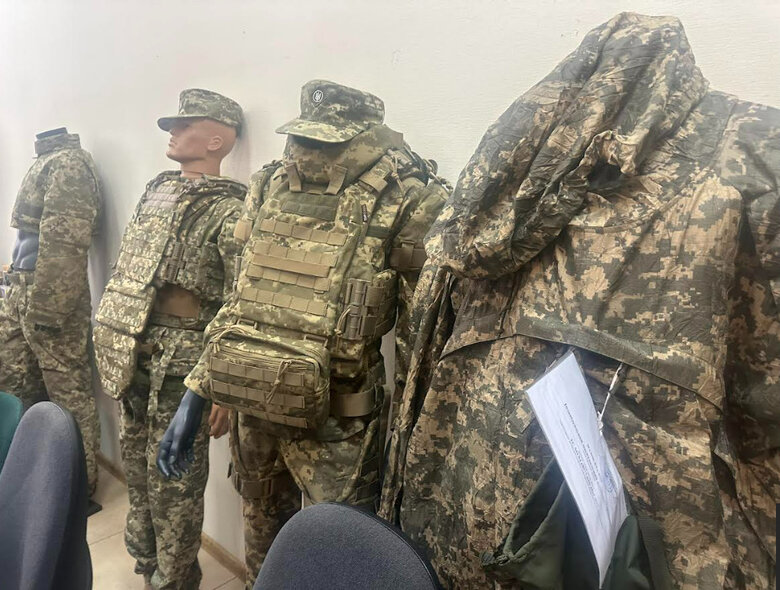

At the same meeting, it turned out that all the jackets that were sewn in Ukraine were made using the Cherkasy Silk Mill's fabric.

The head of the Association of Light Industry, Tetiana Izovit, spoke about the new Cherkasy Silk Mill's technology and that the fabric was good. They even agreed that the fabric would receive a conclusion from one of the scientific and research institutes.

But the positive tone of the July meeting changed dramatically in August.

"The organoleptic method revealed that the appearance and stiffness of the fabric differed from the approved reference sample. The jacket is quite stiff, not very pleasant to the touch," said a representative of the Central Department for Development and Support of Material Support of the Armed Forces of Ukraine.

The results of the analysis showed that the polyurethane-coated fabric is highly waterproof. However, it is inferior to fabrics with a microporous coating and has lower vapour permeability, which "can negatively affect the microclimate inside the product during active use".

In addition, at low temperatures, the polyurethane coating can also lose elasticity, which leads to cracks on the surface.

But all this is just a rough estimate, because the real impact on the fabric can only be assessed in freezing temperatures during daily wear, said Tetiana Kucher, a specialist at the Central Department for Development and Support of Material Support of the Armed Forces of Ukraine.

"Therefore, we are not going to approve this fabric and can only conduct military tests in winter, when we can move forward based on the results of the military's feedback," said Maksym Kaiola, head of the Collegial Body.

It is likely that the mood of the Ministry of Defence staff has changed significantly after Ihor Leshchenko, head of the Quality Control Department, received a suspicion from the SBI last week.

Moreover, the change in fabric is already public knowledge. Therefore, if the quality turns out to be worse and the TU were violated, the representatives of this particular unit of the Ministry of Defence will be questioned by the SBI, SSU and NABU for the compliance certificate. However, no one wants to go to jail or be interrogated.

But these are the risks from the point of view of a Ministry of Defence employee.

How does this currently threaten the Armed Forces? Both Mykyta Chychkan, a representative of the "State Logistics Operator", and Ukrainian manufacturers admitted that most of the fabric for the jackets was produced by the Cherkasy Silk Mill. Only a small part was imported from China.

Thus, it is already clear that the 50,000 jackets that were supposed to be delivered in September will not be received by the military on time.

Moreover, the delivery of another 50,000 in November is under threat.

As Censor.NET was assured by Borys Timonov, the plant has already started producing the fabric, but no one will receive it by September. And even if the fabric does arrive in the coming months, all the manufacturers who need two or three months to sew jackets will delay deliveries.

The jackets may arrive when we need summer clothes.

The news from Collegial Body obviously upset the jacket suppliers, who were clearly counting on the Central Department for Development and Support of Material Support of the Armed Forces of Ukraine to approve the fabric. Now, they are getting hit with fines at very low price if the SLO does not approve the force majeure circumstances for them.

Tetiana Nikolaienko, Censor.NET